- Portable for transfer of non-flammable liquids and chemicals with specific gravities up to 1.3

- Built-in flapper/check valve permits self-priming to 6 feet

- 300 series cast stainless steel with Teflon seals or bronze with Viton seals for resistance to corrosion and chemicals

- Handles liquids with specific gravities up to 1.3 and viscosities to 100 SSU

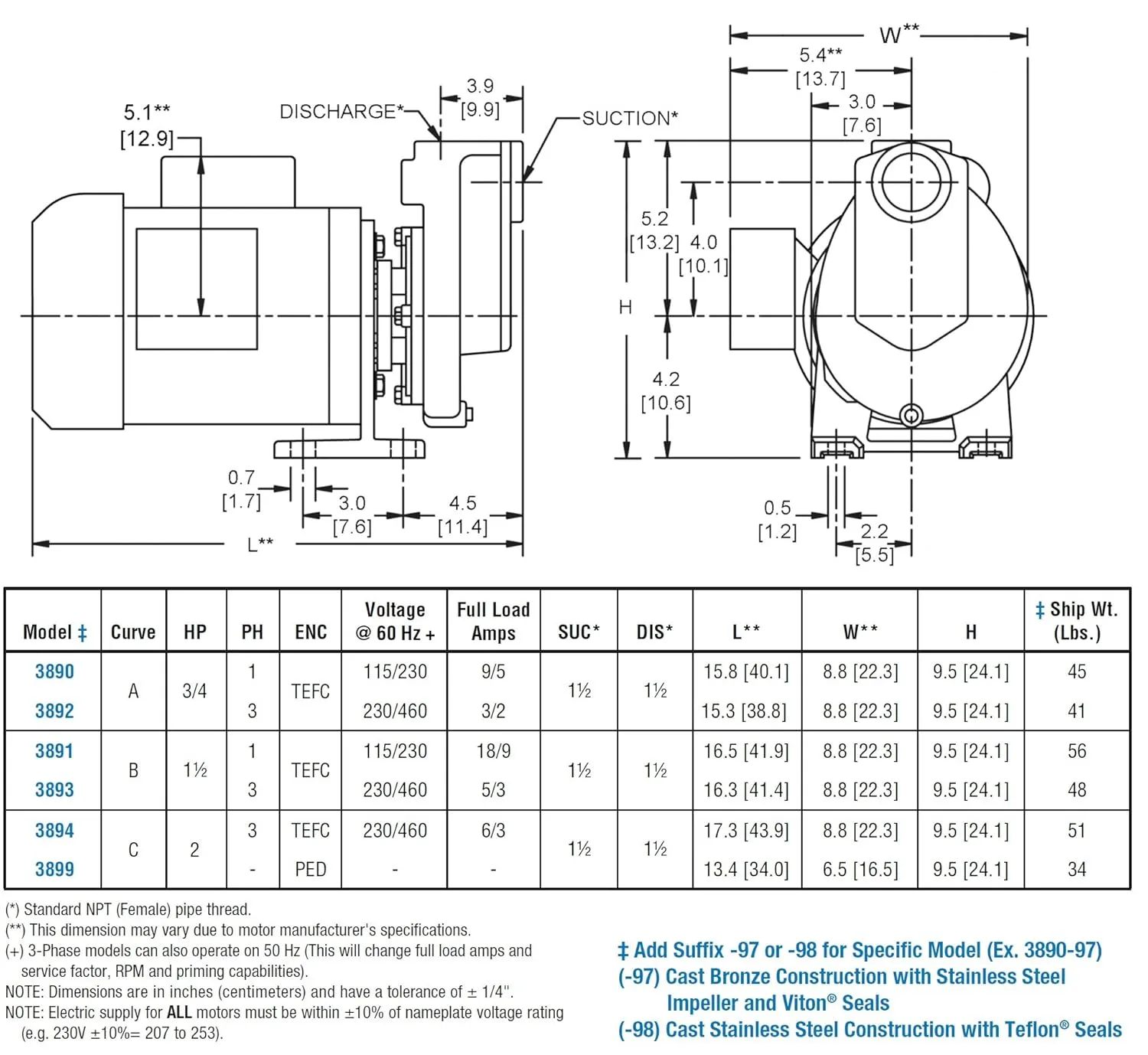

- 1-1/2" female NPT suction port, 1-1/2" female NPT discharge port

This AMT self-priming centrifugal chemical pump has 1-1/2" female NPT suction and discharge ports. The pump is self-priming to 6 vertical feet (after initial fill) with its built-in check valve, and it handles liquids with specific gravities up to 1.3 and viscosities to 100 Saybolt Seconds Universal (SSU). The pump housing is either 300 series cast stainless steel with Teflon seals or bronze with Viton (FKM, fluoroelastomer) seals, depending on the model, for resistance to corrosion and chemicals and has a double volute chamber for reduced radial load on the impeller. The motor enclosure is totally enclosed, fan cooled (TEFC) for protection from dust and indirect water. This portable pump is suitable for use in applications such as chemical transfer, waste water treatment, and pumping agriculture fertilizers and fumigants.

Specifications

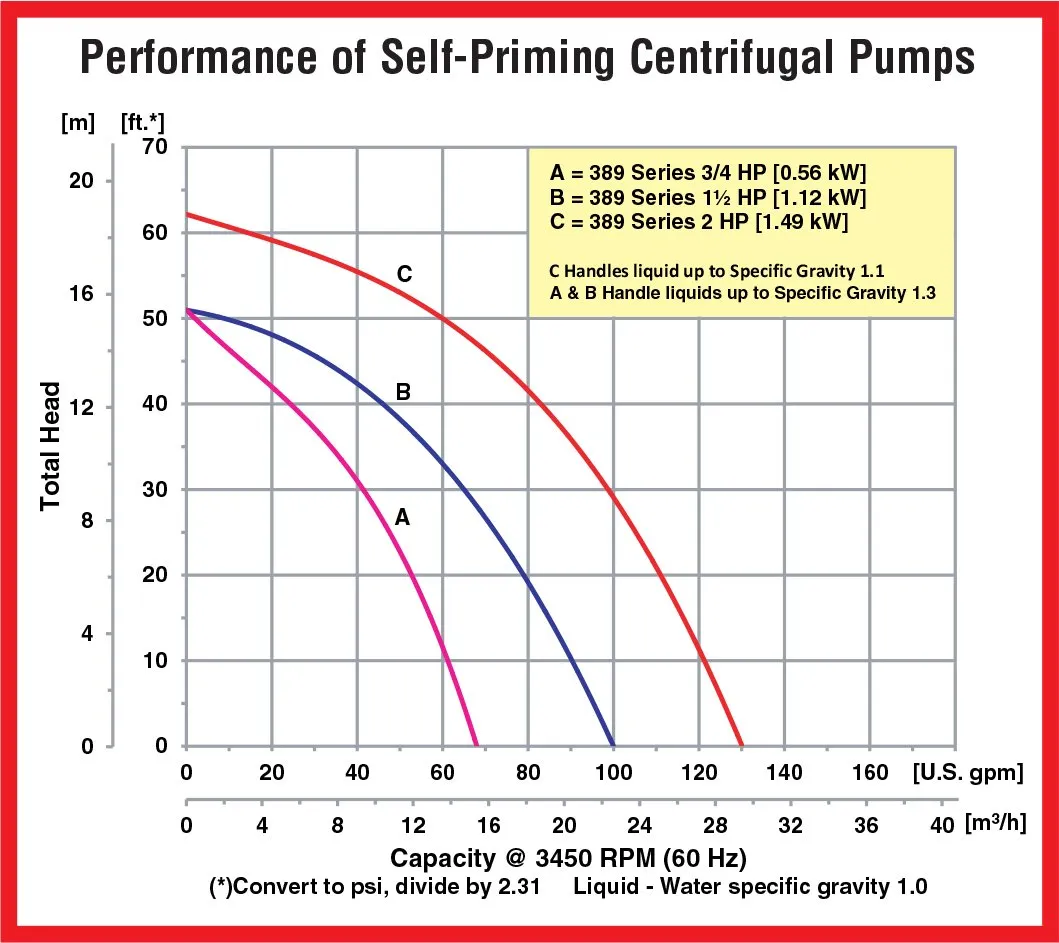

Motor0.75 to 2 hp, TEFCPumpCentrifugal self-priming with dual voluteMaximum flow rateRanges from 70 to 130 gpmImpellerStainless steel self-cleaning, semi-openSuction port1-1/2" NPTDischarge port1-1/2" NPTMaximum operating temperatureRanges from 200 to 250 degrees FMaximum liquid specific gravity1.3Maximum liquid viscosity100 SSUPumps use mechanical action to move liquids, gases, or slurries (solids suspended in a liquid or gas). The mechanical action is categorized as either positive displacement (PD) or kinetic. PD pumps capture and release discrete amounts of flow into a chamber and then force it out. Some examples of PD pumps are fuel and oil pumps in cars, pumps in hydraulic systems, and bicycle pumps. Kinetic pumps move liquids, gases, or slurries by transferring energy from the pump's movement to the flow. They use an impeller to draw the flow in, add energy to the flow, and move it through a volute (a spiral funnel through which the flow moves), and into the system. Some examples of kinetic pumps include centrifugal (the most common pump in industrial applications), in-line pumps, sump pumps, and suction pumps. Energy sources for all types of pumps include wind power, manual operation, electricity, and gasoline or diesel fuel.

American Machine and Tool (AMT) manufactures centrifugal and diaphragm pumps. The company is headquartered in Royersford, PA.

- Product Dimensions : 15.8 x 8.8 x 9.5 inches; 43 Pounds

- Date First Available : May 14, 2012

- Manufacturer : AMT Pumps